23 Participated the Intermold Korea 2023

19 Participated in the Vietnam Plastics Industry Exhibition (2019 Vietnam Plas)

EVERFINEST HotRunner System Partnerships

17 Participated in the Japan International Plastics Exhibition (2017 IPF)

15 Engineering Plastics Recycler RM-32D Development and Manufacturing,

Development and Manufacturing of DMK-40-400 Mold Vacuum System

14 Agency agreement with NS TOOL (Nisshin Tool) in Japan

: Started selling ultra-precision end mills

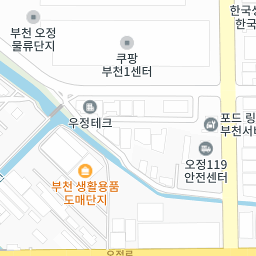

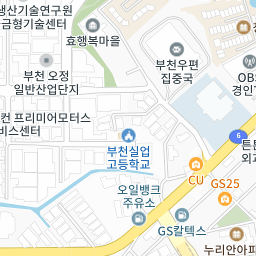

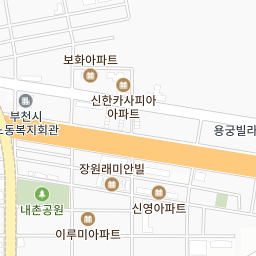

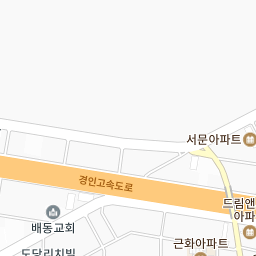

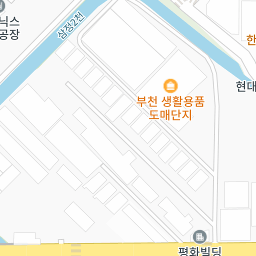

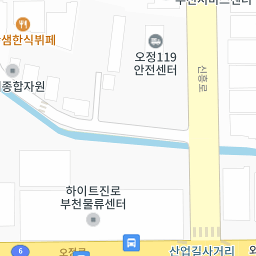

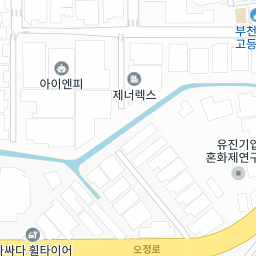

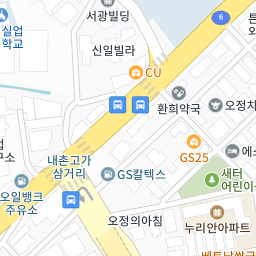

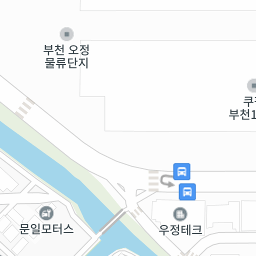

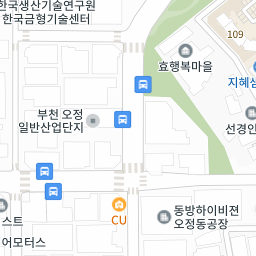

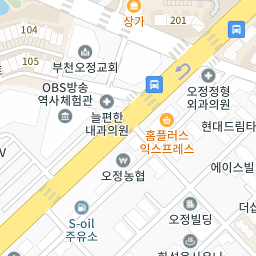

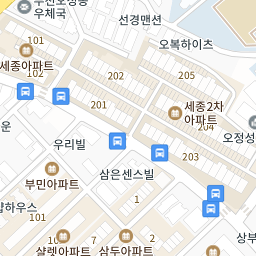

12 Completed the 2nd factory in Bucheon-si, Gyeonggi-do [in Ojeong Industrial Complex]

Good Faith Taxpayer Recognition [Internal Revenue Service]

11 Registration Technology Innovative Small Business (INNO-BIZ)

[Small and Medium Business Administration]

10 Registering an Innovative Small Business (MAIN BIZ)

[Small and Medium Business Administration]

08 Development of the MICRO-1 injection molding machine for connectors

07 Establishment of a company-affiliated R&D center

06 Utility model registration: Ultra-small comprehensive precision machine No. 20-434287

[Korea Patent Office]

Developing an ultra-compact composite automated injection molding machine

Registration of specialized parts and materials companies

[the Minister of Commerce, Industry and Energy]

04 Microswitch and Automotive Connector Injection Parts Start Production

ISO 9001:2000 Renew authentication,

Utility Model Registration: Cassette-type plastic shredder - No. 0357632

[Korean Patent Office]

Completion of the Automation Division's 2nd Shihua Plant

03 Established the 2nd factory in Sihwa Industrial Complex,

Jeongwang-dong, Siheung-si, Korea,

[2nd Plant, Automated Equipment Manufacturing, Injection Molding Plant]

02 Started OEM production of FRP-V32 engineering plastics recycling machine,

Launching an engineering plastics recycling business

01 First in its class to receive ISO 9001-2000 certification [UKAS, UK]

00 Started production of semiconductor mold parts